The Comeback of Variable Compression Engines

Pushing the boundaries of internal combustion efficiency, variable compression engines are making a surprising resurgence in the automotive world. This innovative technology, once considered too complex for mass production, is now poised to reshape the landscape of gasoline-powered vehicles. Join us as we explore the intricate workings, potential benefits, and challenges of this cutting-edge engine design that's turning heads in the industry.

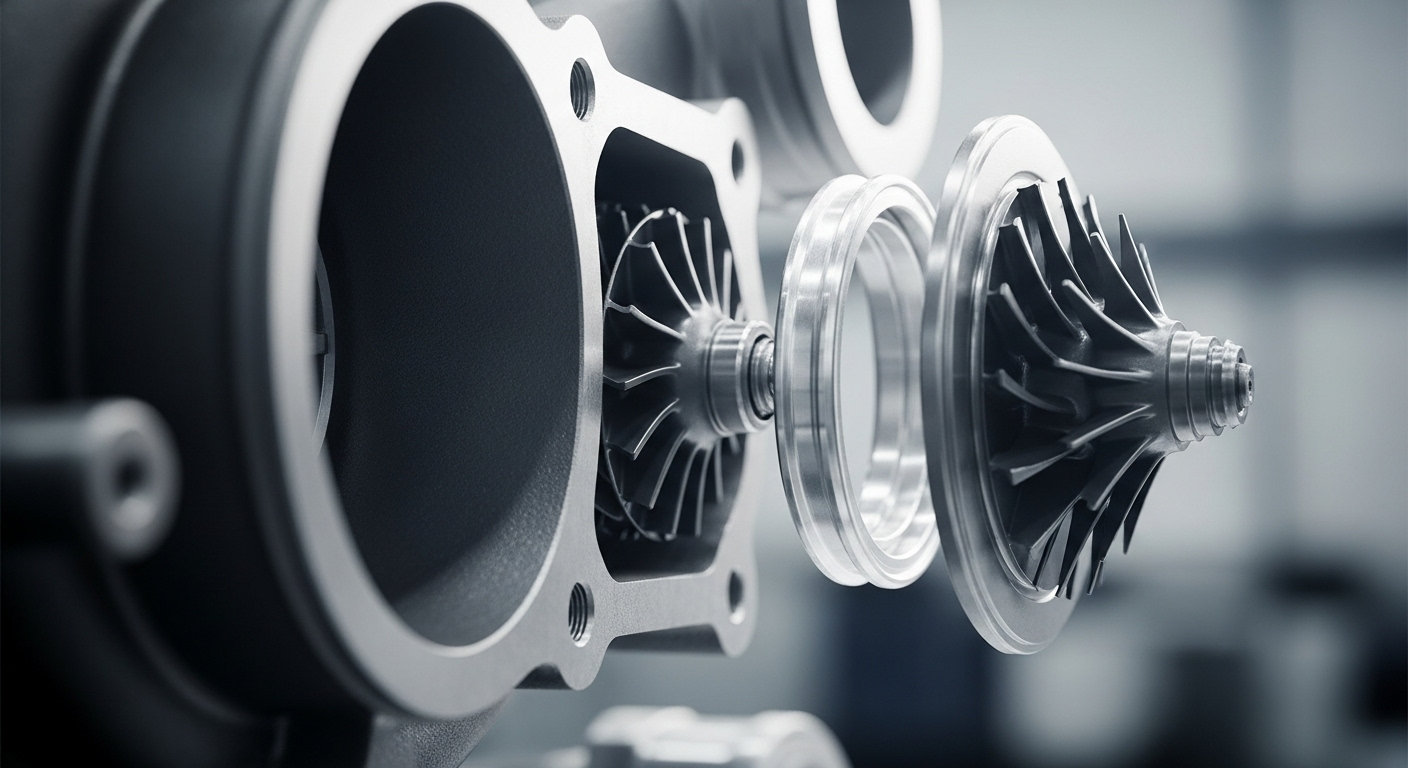

The Mechanics Behind Variable Compression

At its core, the variable compression engine relies on a sophisticated system of linkages and actuators to alter the volume of the combustion chamber. This is achieved by adjusting the position of the piston’s top dead center, effectively changing the engine’s compression ratio. The ability to vary this ratio allows the engine to operate at peak efficiency regardless of load or speed.

Traditional engines are designed with a fixed compression ratio, which is always a compromise between power and efficiency. Low compression ratios favor high-performance applications but sacrifice fuel economy, while high compression ratios improve efficiency but can lead to knocking and reduced power output. Variable compression solves this dilemma by offering the best of both worlds.

Historical Context and Early Attempts

The concept of variable compression is not new. As early as the 1920s, engineers were experimenting with ways to adjust an engine’s compression ratio. However, these early attempts were often complex, unreliable, and impractical for mass production. Notable efforts include the Saab Variable Compression engine in the early 2000s, which never made it to production due to technical challenges and cost concerns.

Despite these setbacks, the potential benefits of variable compression continued to captivate automotive engineers. The promise of significantly improved fuel efficiency and performance in a single package was too enticing to abandon. As technology advanced and manufacturing techniques improved, the dream of a commercially viable variable compression engine inched closer to reality.

Modern Implementation and Breakthrough Technologies

The breakthrough came with the introduction of production-ready variable compression engines in the late 2010s. These modern iterations utilize advanced materials, precision manufacturing, and sophisticated electronic controls to overcome the challenges that plagued earlier designs. One of the most notable examples is the VC-Turbo engine, which employs a multi-link system to adjust the piston’s stroke and, consequently, the compression ratio.

This technology allows for an impressive range of compression ratios, typically from 8:1 to 14:1, which can be seamlessly adjusted in real-time. The lower ratios enable high power output when needed, while the higher ratios maximize fuel efficiency during cruising or light-load conditions. The result is an engine that can deliver V6-like performance with the fuel economy of a much smaller four-cylinder unit.

Benefits and Performance Gains

The advantages of variable compression engines extend beyond just balancing power and efficiency. These engines offer improved thermal efficiency, reduced emissions, and enhanced low-end torque. By optimizing the compression ratio for each operating condition, they can extract more energy from each drop of fuel, leading to significant gains in overall engine efficiency.

Performance enthusiasts will appreciate the ability to dial in the perfect compression ratio for maximum power when needed, without sacrificing daily drivability. Meanwhile, the improved fuel economy and reduced emissions make variable compression engines an attractive option for automakers striving to meet increasingly stringent environmental regulations.

Challenges and Future Outlook

Despite its promising benefits, the widespread adoption of variable compression technology faces several hurdles. The complexity of these engines leads to higher manufacturing costs, which can be a significant barrier in the price-sensitive automotive market. Additionally, the increased number of moving parts raises concerns about long-term reliability and maintenance requirements.

However, as the technology matures and economies of scale come into play, these challenges are expected to diminish. Several major automakers have already expressed interest in incorporating variable compression engines into their future lineups, signaling growing confidence in the technology’s viability.

Integration with Hybrid Systems

Perhaps one of the most exciting prospects for variable compression engines lies in their potential integration with hybrid powertrains. By combining the efficiency gains of variable compression with the instant torque and energy recovery capabilities of electric motors, automakers could create hybrid vehicles with unprecedented levels of performance and fuel economy.

This synergy could provide a compelling alternative to full electrification, especially in markets where charging infrastructure is still developing. It could also serve as a bridge technology, allowing automakers to significantly reduce emissions from their gasoline-powered models while continuing to invest in electric vehicle development.

The Road Ahead for Variable Compression

As the automotive industry continues to evolve, variable compression engines represent a fascinating example of how traditional technologies can be reinvented to meet modern challenges. While electric vehicles may dominate headlines, the resurgence of variable compression serves as a reminder that internal combustion engines still have room for significant innovation.

The coming years will likely see further refinement of variable compression technology, with potential advancements in materials science and control systems leading to even greater efficiency gains. As these engines make their way into more vehicles across different segments, drivers will have the opportunity to experience firsthand the benefits of this cutting-edge technology.

In conclusion, the comeback of variable compression engines marks an exciting chapter in automotive engineering. By pushing the boundaries of what’s possible with internal combustion, this technology offers a glimpse into a future where efficiency and performance coexist in perfect harmony. As the industry continues to navigate the complex landscape of powertrain options, variable compression engines stand out as a testament to the enduring ingenuity of automotive engineers.